The Owners of this townhouse, situated at the storied heart of Beacon Hill, knew the property was a gem hiding behind several years of neglect and set out to renovate it inside and out. They wished to completely reorganize the…

Our software entrepreneur clients loved their split-level mid-century modern house and its private, heavily-wooded acreage surrounded by an Audubon Sanctuary. They initially hoped to substantially renovate and add on to the house they had lived in for many years, matching new and old into a seamless whole. However, a thorough review of multiple renovation strategies and their associated costs, in coordination with local contractors, revealed that it would be less expensive and less time-consuming to both start from scratch and to use a custom designed prefabrication project delivery method. The original house was much loved, but there was just too much deferred maintenance and our engineers concluded that the existing foundation was inadequate to meet basic structural needs.

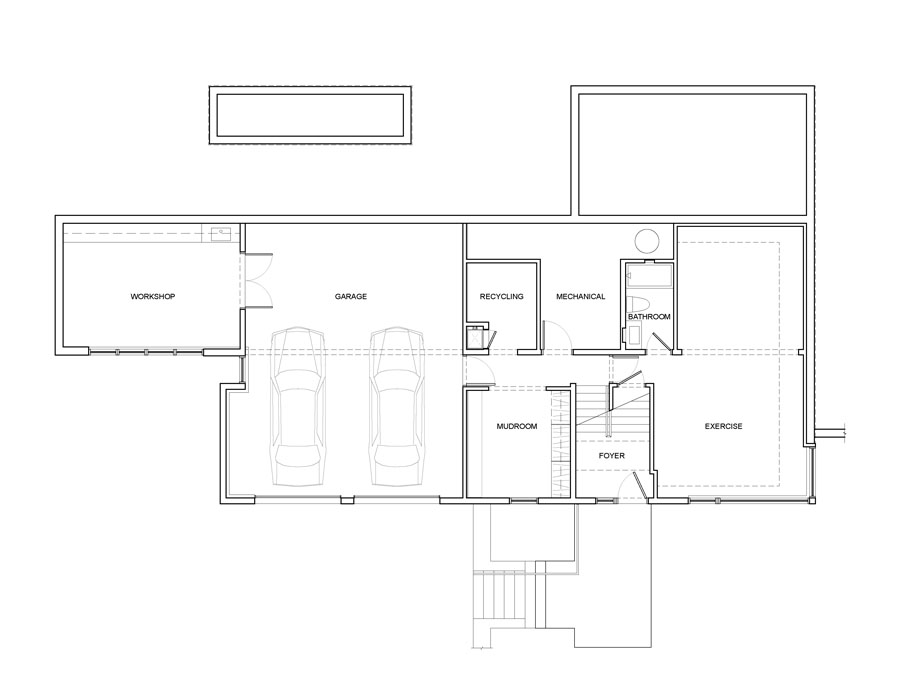

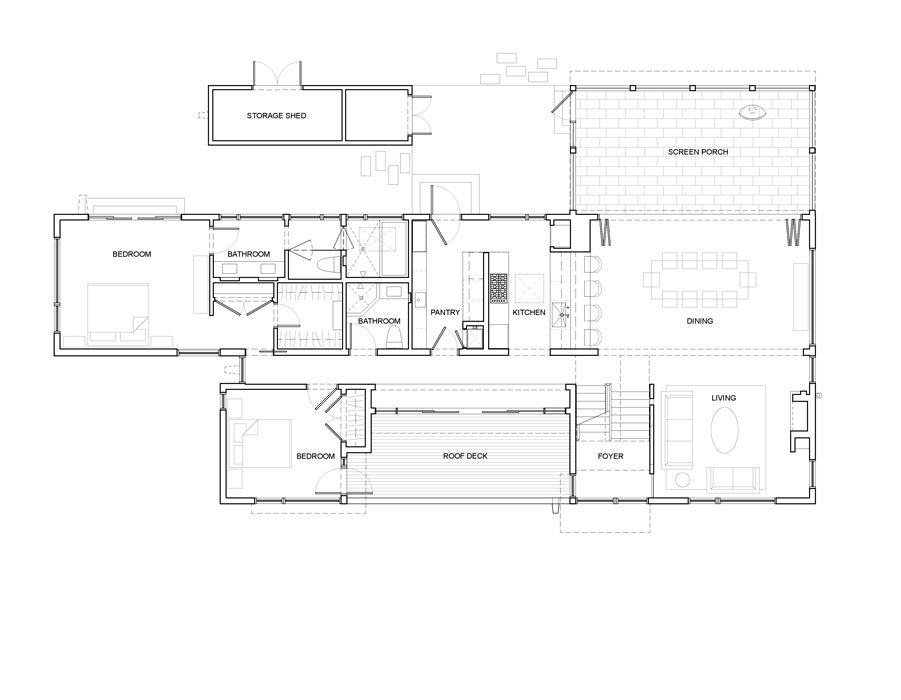

Zoning restrictions required working within the existing house’s footprint; however reconceiving the form of the house above the foundations had the benefit of allowing for a design freed from the constraints and planning inefficiencies of the original house and its long narrow hallways and miniscule kitchen and bathrooms.

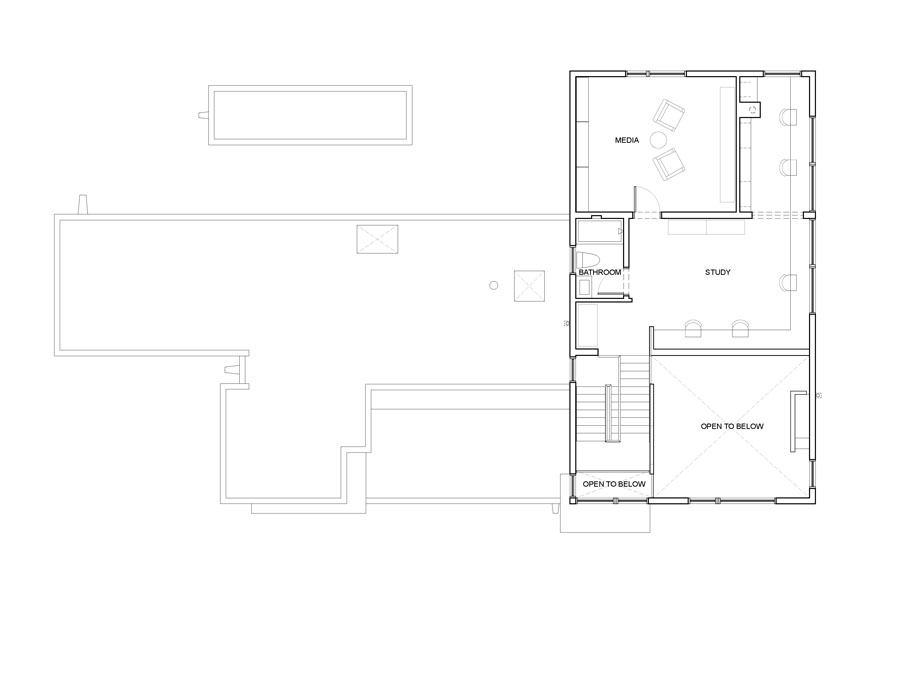

Adding an expansive office space and sound isolated listening room on a mezzanine level freed up space on the main floor for a south-facing “courtyard” where the original tiny office and exercise room had been. The courtyard separates the bedroom area from the living area, and brings much-needed winter sun deep into the heart of the house. The new house has a more varied three-dimensional character, with a twenty foot high living space and dramatic sculptural steel staircase set in a three-story high glass-walled foyer.

The overtly modern and crisply orthogonal design of the house lent itself easily to the efficiencies of off-site modular prefabrication. The entire house is made of nine modules that were carefully planned to be built in a factory in Pennsylvania and transported safely through four states, each having their own unique highway transportation requirements. All modules were custom prefabricated complete with pre-installed wiring, rough and finished plumbing, fire suppression sprinkler system, lighting, wall and ceiling finishes, doors and windows, insulation, trim, etc. -- virtually everything except wood flooring and custom cabinetry that was built locally. Fabrication took two months after the building permit was issued, and assembly of the nine modules on site took only three days. Interior finishes and stitching together of exterior finishes took an additional four months, a substantially shortened time frame relative to traditional residential construction, and the final costs came in below what one would expect locally for a conventionally built house.

All Images

Location

Lincoln, MA

Services

Completion

2012

Architectural Team

William T. Ruhl, FAIA

Sandra A. Jahnes, AIA, LEED AP

Nerijus Petrokas, LEED GA

Ruhl Walker Architects

General Contractor

Sea-Dar Construction

Landscape Design

Matthew Cunningham Landscape Design

Photography

© Ruhl Walker Architects